The B-type Replacement (BR) Systems are designed to provide refrigerated air to small-medium spaces. BR evaporators were designed to replace other systems of a similar configuration. They are often mounted on a shelf or on the wall within the racking design. Like other systems, these operate on system pressure therefore eliminating the need for control wiring to the condensing unit. This makes for a simpler installation.

The B-type Replacement (BR) Systems are designed to provide refrigerated air to small-medium spaces. BR evaporators were designed to replace other systems of a similar configuration. They are often mounted on a shelf or on the wall within the racking design. Like other systems, these operate on system pressure therefore eliminating the need for control wiring to the condensing unit. This makes for a simpler installation.

BR Systems are available in capacities from 2, 600-5,200 BTUH.

Wine Cellar Refrigeration Unit Features

- Title 24 compliant

- Black coated aluminum housing

- Seamless copper tubing throughout

- Universal AXV and liquid line solenoid valve

- Pre-installed valves (eliminated additional wiring)

- Epoxy-coated coil (water-basedl reduces corrosion)

Available Wine Cellar Refrigeration Options

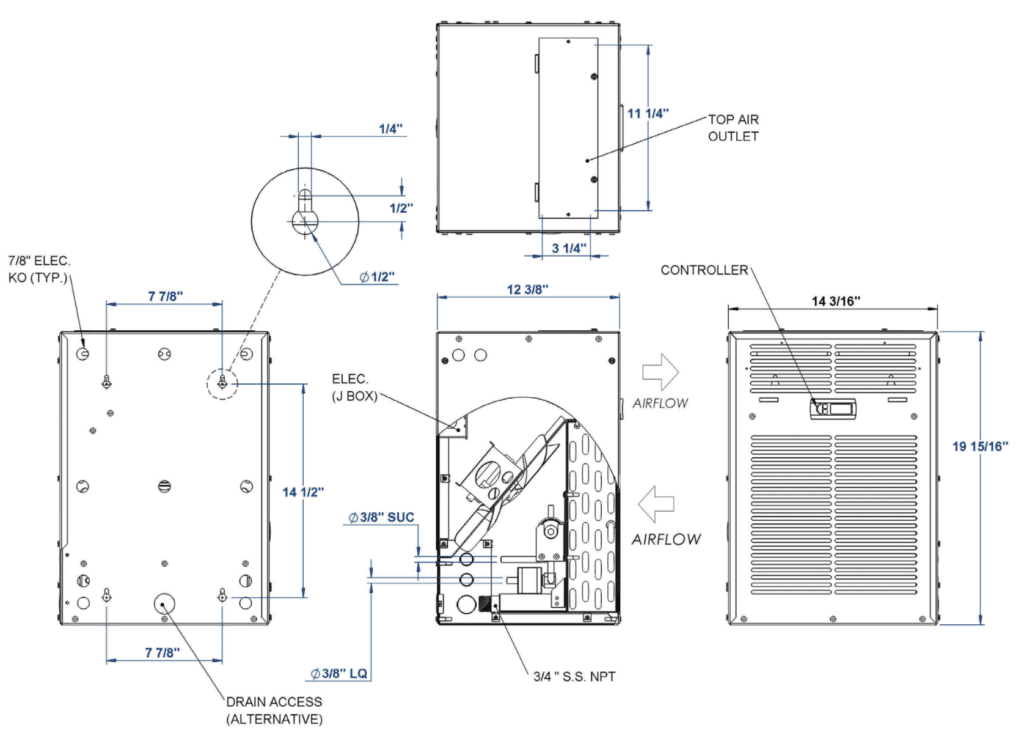

BR cooling units are 14 3/16” x 19 15/16” x 12 3/8” (w x h x d) in size with a suction length of 3/8” and a drain length of ¾”. At 30lbs, this powerful wine cellar refrigeration system operates at an airflow volume of 350CFM.

Options available:

- Digital remote controller mounted on the unit

- 230v

- Additional evaporators for large rooms

Click here to download the full pdf version of this page.

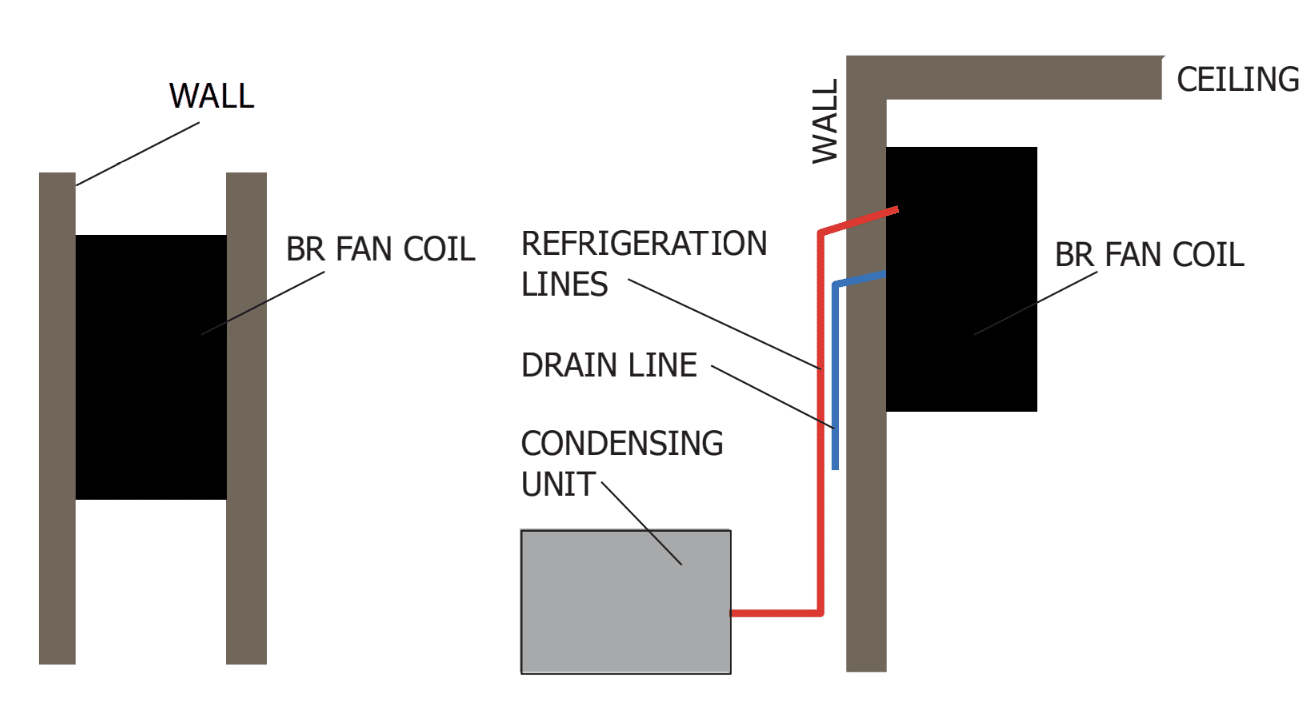

BR Cooling System Typical Installation

- Always plan for future maintenance and service. Units should be easily accessible. Grills, boxes, or racking nearest the evaporators should be removable.

- Standard Line Sets should be 50’ or less. Over 50’, an oil separator and suction line accumulator is required.

- Extended runs may require larger line sizes and 3 ounces of oil must be added for every 10 feet intervals, after 35 feet.

- Insulated suction line. Insulating liquid line is optional.

- Excessive number of turns in line set will cause refrigerant flow problems, potentially resulting in early compressor failure. Suction line accumulators are recommended for all applications. This is required when operating below the normal 55°-65°F wine cellar temperature range.

- The drain line must flow downward.

- The system is controlled by a pump down control system.

- There is no control wiring between the thermostat and condensing unit.

- The line connections at the fan coil and condensing unit may not be the same as the required line sizes dictated for the system capacity.

- The use of oversized condensing units can lead to poor wine room evaporator performance and possible system failure.

- When installing the wine room evaporator, it is recommended that the condensing unit is less than or equal to the evaporator’s capacity.

- USCS wine cellar refrigeration systems are designed to reduce noise and vibration. To reduce and eliminate amplification of existing noise or vibration, extreme care must be observed during installation.