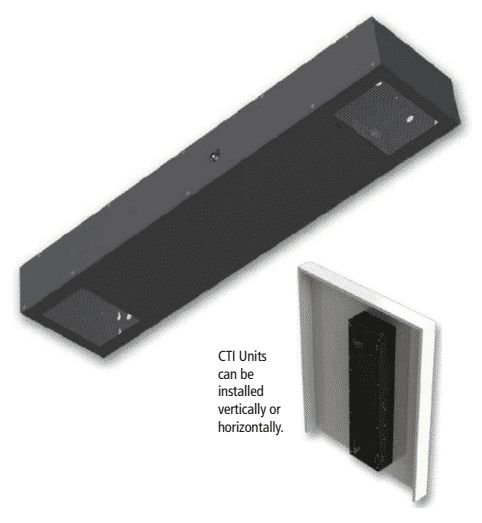

The Cabinet Top Internal (CTI Series) wine cellar refrigeration systems are small cooling units designed for medium to large-sized, humidity-controlled spaces such as wine cabinets/walls, fur cabinets, and tobacco humidors.

CTI Evaporators have a 6” profile to minimize cooling unit space and can be installed horizontally in or near the top of a cabinet or vertically on the back or side of a cabinet for maximum flexibility.

CTI Evaporators are available in capacities from 1,537 to 3,546 BTU/hour and can be used with R22, R134a, or R404a refrigerants. Chilled water models are available by special order.

Features

- Very low noise

- Provides consistent humidity by maintaining a steady coil temperature, reducing the need for expensive temperature and humidity controls in most applications*.

- Rust-proof aluminum housing with flat black powder-coated finish. Other colors are available.

- Constant pressure expansion valve standard

- Thermally protected, PSC motorized impeller

- High performance staggered coils with copper tubing mechanically expanded into aluminum fins

- Each unit is pressure-tested to eliminate leaks.

- Factory wired for easy field installation

- Coil and drain pain dipped and baked with LRCCoat™ anticorrosion coating

Available Options

- Copper coils and/or stainless steel cabinets available for special applications

- Chilled water coils are available

- Pre-charged, custom, or OEM units can be made to order

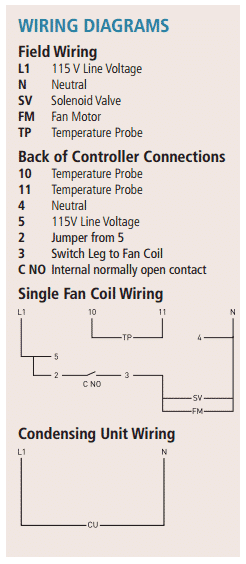

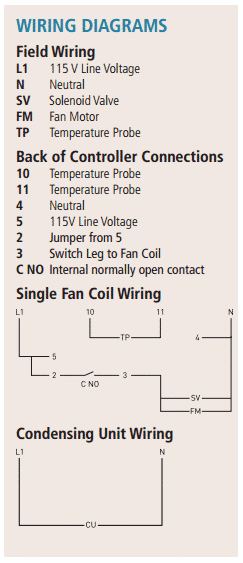

Visit www.uscellarsystems.com for installation and maintenance data, as well as wiring diagrams.

Our Application Engineers can help you design the system you need. Call us today, at (562) 513-3017 and we’ll help you get the right product for your project.

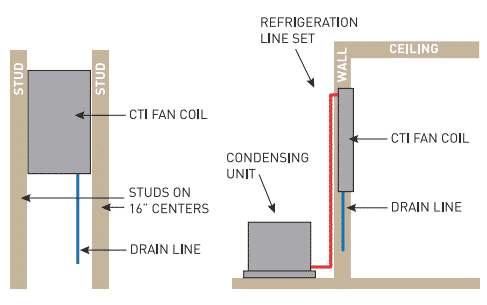

CTI Vertical Series

CTI Cooling System Typical Vertical Installation

- Keep line sets as short as possible.

An excessive number of turns will cause refrigerant flow problems. This could cause early compressor failure. Suction line accumulators are recommended. Required if working lower than the normal 55-65 degrees operating range from the wine cellar

An excessive number of turns will cause refrigerant flow problems. This could cause early compressor failure. Suction line accumulators are recommended. Required if working lower than the normal 55-65 degrees operating range from the wine cellar- The drain line must always flow downhill to drain or pump

- The system is controlled by a pump-down control system. There is no control wiring between the thermostat and condensing unit

- The line connections at Fan Coil and Condensing Unit may not be the same as the required line sizes.

- Standard line sets should be 50′ or less. Extended runs may require larger line sizes and 3oz. oil must be added for every 10′ over 35′

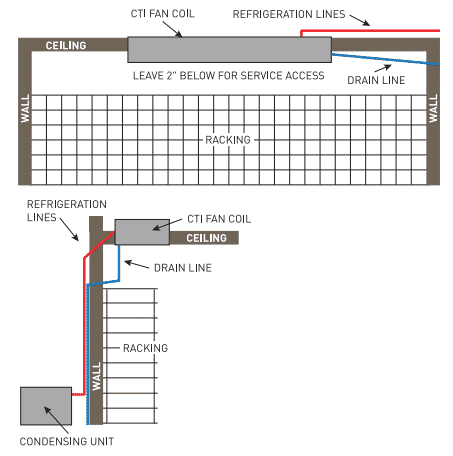

CTI Horizontal Series

CTI Cooling System Typical Horizontal Installation

- Keep line sets as short as possible.

An excessive number of turns will cause refrigerant flow problems. This could cause early compressor failure. Suction line accumulators are recommended. Required if working lower than the normal 55-65 degrees operating range from the wine cellar

An excessive number of turns will cause refrigerant flow problems. This could cause early compressor failure. Suction line accumulators are recommended. Required if working lower than the normal 55-65 degrees operating range from the wine cellar- The drain line must always flow downhill to drain or pump

- The system is controlled by a pump-down control system. There is no control wiring between the thermostat and condensing unit

- The line connections at Fan Coil and Condensing Unit may not be the same as the required line sizes.

- Standard line sets should be 50′ or less. Extended runs may require larger line sizes and 3oz. oil must be added for every 10′ over 35′

GO HERE TO SEE other wine cellar refrigeration units by US Cellar Systems.