Rack Mounted Ducted / Air or Water Cooled Condensing Unit Ducted Evaporator with Digital Controller

The Rack Mounted Ducted (RMD EC) Systems are designed

to provide refrigerated air to medium and high temperature

spaces.

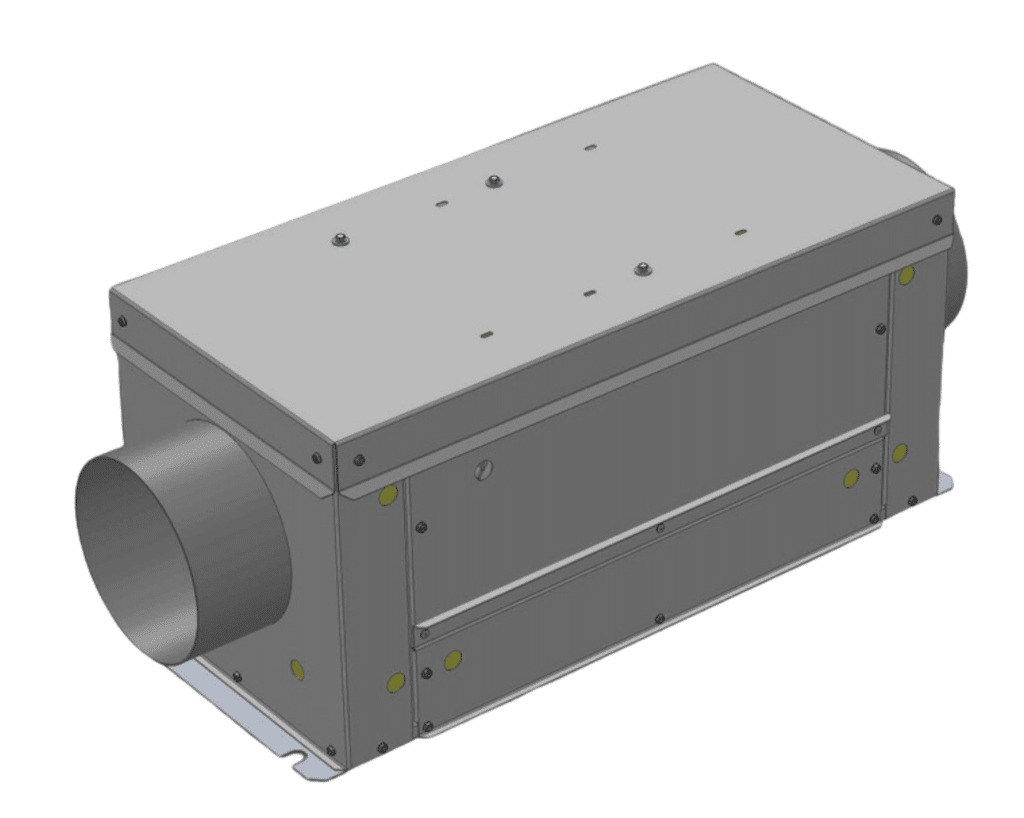

RMD evaporators are internally insulated and mounted outside of the wine room. RMD units are connected by a supply and return air duct to the cellar.

These units are extremely low profile, so they may fit in places no other ducted evaporator could.

Wine Cellar Refrigeration Unit Features

• High-performance staggered

• Coils with copper tubing mechanically expanded into aluminum fins

• Insulated rust-proof aluminum housing

• Thermally protected, permanently lubricated motor

• Automatic expansion valve (standard) ensures constant coil temperature to promote “Humidity Balance”

• Pump-down solenoid valve (standard) protects compressor in the event of leaks

• Pre-installed valves eliminate additional wiring to thermostat

• Pressure tested by the manufacturer to ensure quality

• Factory wired for simple field installation

• ETL certified

Available Wine Cellar Refrigeration Options

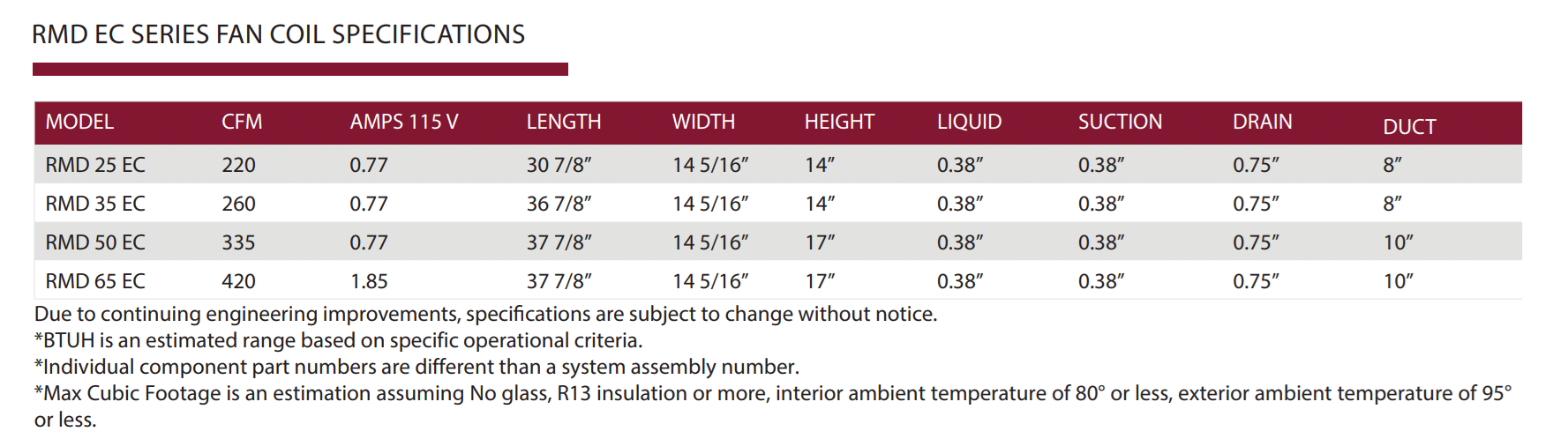

RMD EC evaporators are available in standard capacities from 1,800 to 7,200 BTUH and are used with R134a, R404, R410A, R22 all by a simple valve adjustment.

Options available:

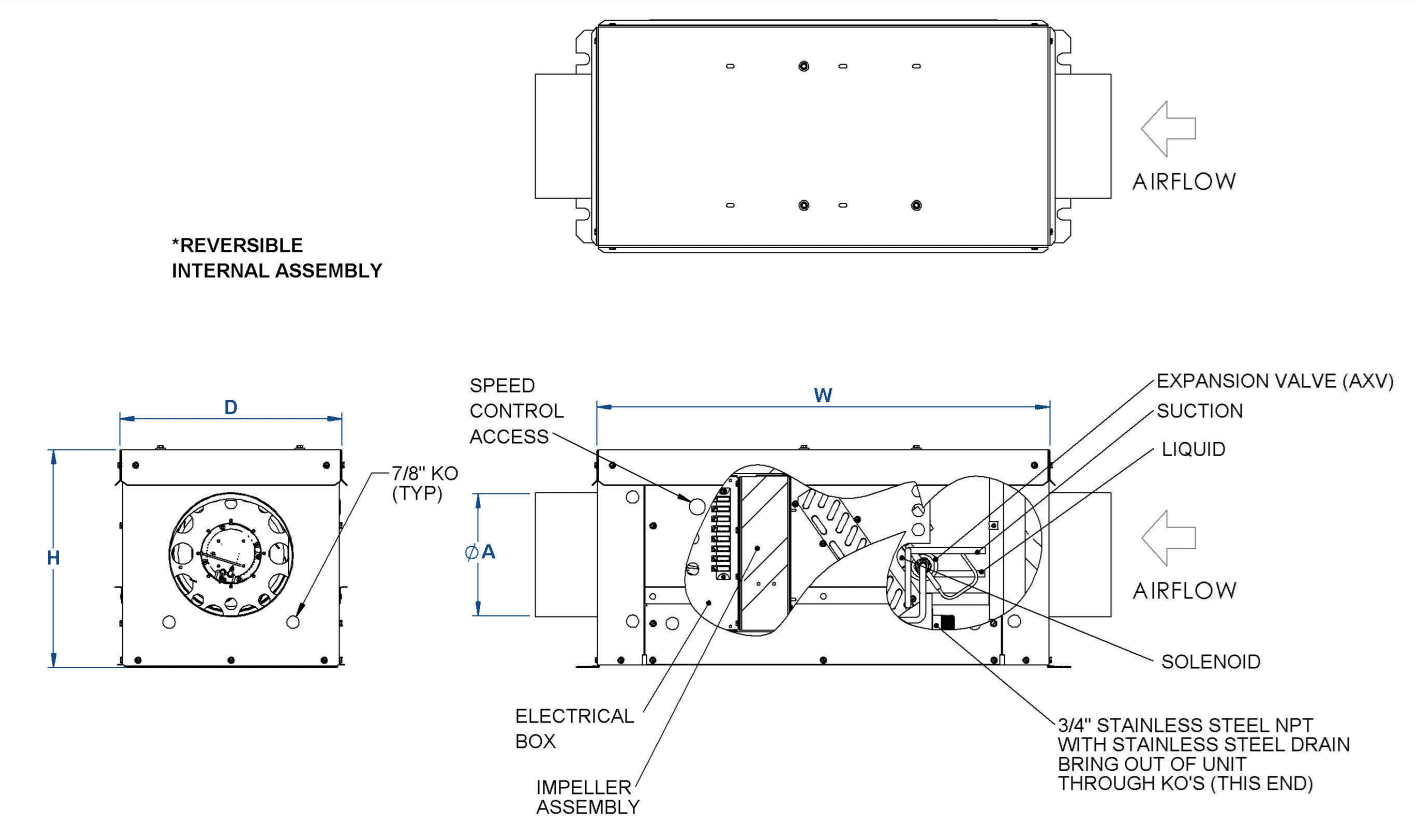

• Reversible internal assembly

• Secondary Drain Pan available

• 230v available

• Can be installed in sequence to increase capacity

Click here to download the full pdf version of this page!

Mounting Diagrams

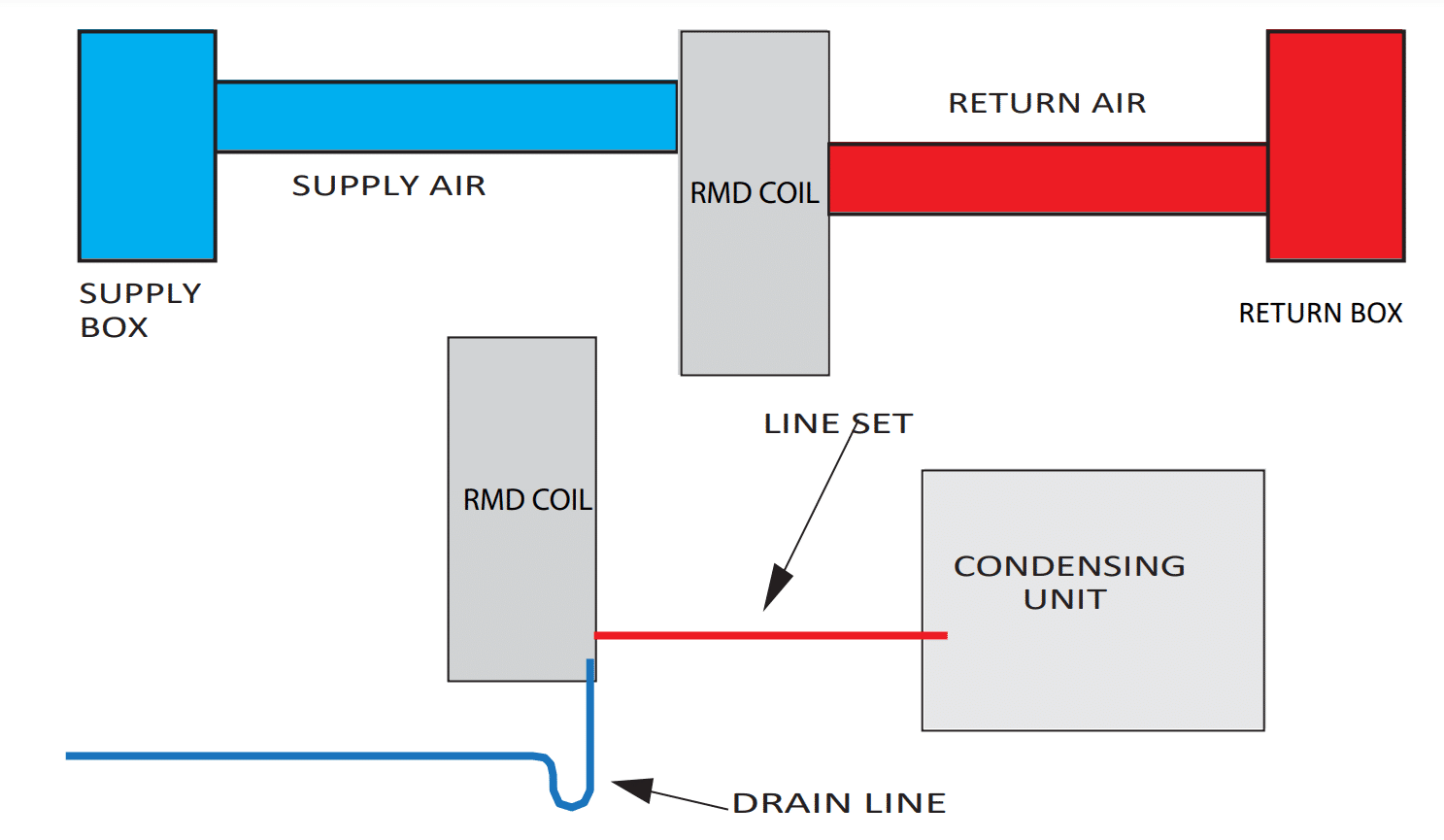

RMD EC Cooling System Typical Installation

• Always plan for future maintenance and service. Units should have easy access or access panels. Grills, boxes, or racking nearest the evaporators should be removable.

• Standard Line Sets should be 50’ or less. Over 50’ an oil separator and suction line accumulator is required. Extended runs may require larger line sizes and 3 oz of oil must be added for every 10’ feet over 35’. Insulate suction line, liquid line insulation is optional.

• Excessive number of turns in line set will cause refrigerant flow problems. This could cause early compressor failure. Suction line accumulators are recommended on all applications. Required if working lower than the normal 55°-65°F operating range from wine cellar.

• Drain line must flow with gravity to drain or pump.

• The system is controlled by a pump down control system. There is no control wiring between thermostat and condensing unit.

• The line connections at Fan Coil and Condensing Unit may not be the same as the required line sizes dictated for the system capacity.

• BTUH Capacity calculated at 17° TD, 38° ST, 55° Room

• The use of oversized condensing units can lead to poor wine room evaporator performance and possible system failure. When installing our wine room evaporator, it is recommended that condensing units be sized less than or equal to the evaporator capacity.

• USCS Cooling units are designed to minimize noise and vibration. To reduce and eliminate amplification of existing noise or vibration, extreme care must be taken during installation toidentify contributing factors in the environment. Please refer to supplied installation instructions and use proper installation materials to minimize acoustic impact.

• Refer to complete installation instructions for additional information or contact our Tech Line at 562-728-5774