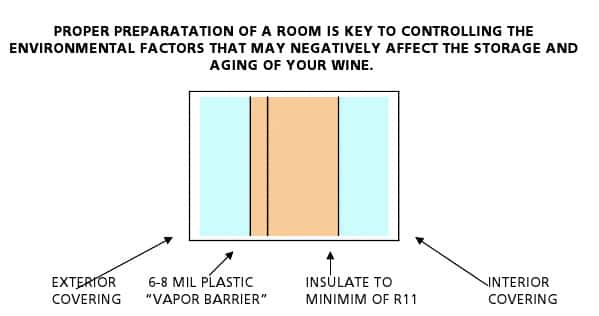

- Walls and ceilings must be protected with a vapor barrier on the “warm side” of the walls.

- Interior walls should be insulated to R19 or higher ceilings to R30. We suggest a rigid foam board and filling gaps/joints with expanding spray foam. Interior walls can be finished with moisture-resistant green-board.

- Doors are solid wood and/or insulated and weatherstripping is used for an air-tight seal.

- Glass is the best dual pane with a 1/2 ” gap and lightning should be minimal.

- Must be considered in sizing of unit (do not size by estimates or charts if the glass is incorporated or more than 2.5 watts sqft of lightning are included in design).

A wine cellar is not an “Air Conditioned” room.

It is a REFRIGERATED room.

Originally, long-term wine storage began in Europe. Fine wines were stored in caves underground; this natural environment it turned out, supports just the right rate for optimally aging wines. Critical factors include avoidance of UV rays from sunlight, vibrations, and most critically, absolutely no fluctuations in temperature or humidity. A custom wine cellar designed to allow the wine to age naturally is, therefore, more than just a refrigerated room. It is a stable environment that sets out to re-create as closely as possible the natural environment found in caves underground. This time-tested and ancient wine storage and aging practice has proven to be effective at producing the best wine aging result over many years and has therefore set today’s standard for wine cellar construction.

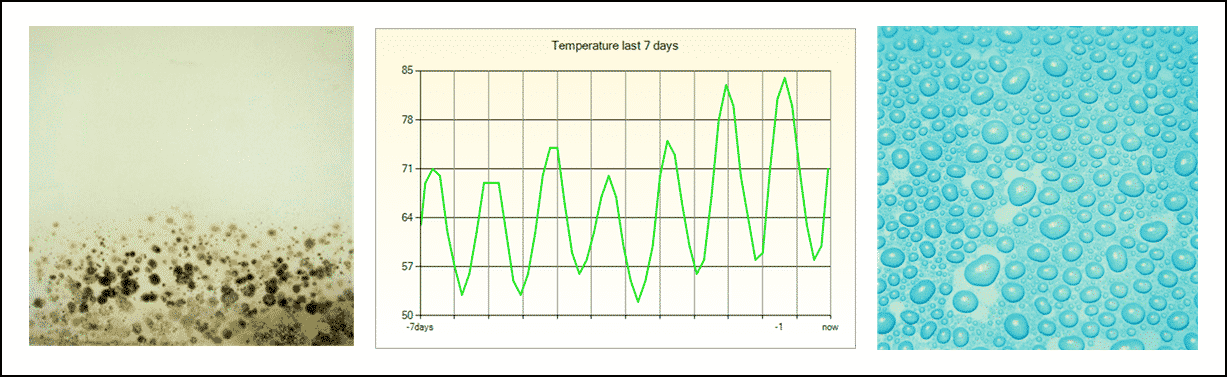

Frequent problems associated with poorly designed wine storage rooms can include; high running costs, prematurely failing cooling units and even mold, and excessive noise from the cooling unit. Most people underestimate the natural day-night and seasonal fluctuations in temperature and humidity that occur in most home and commercial premises.