The Vertical High Static (VHS) wine cellar refrigeration systems are cooling units intended to deliver refrigerated air to medium to high-temperature spaces. You will find these evaporators powerful and can be situated as far up to twenty-five feet distant from the climate-controlled wine room. The cooled air is ducted back into the wine cellar, virtually eliminating any noise and of course, the inconvenience associated with evaporators that have to be placed in the wine cellar. This can also free up storage space otherwise lost.

Robust Wine Cellar Cooling Units for Long Distances from Wine Rooms

VHS evaporators are available in capacities from 1,800 to 20,000 BTUs every hour. To be used with an R134a refrigerant.

Wine Cellar Refrigeration Systems Options

- Copper or coated coils for coastal/special applications

- Secondary drain pan for elevated and sensitive installations

- Stainless steel cabinets for high corrosive environments

- Eco-friendly water-cooled condensing units available

- Industrial applications available

Features

- Thermally protected permanently lubricated motor

- The automatic expansion valve (standard) ensures constant coil temperature to promote “Humidity Balance”

- Pump-down solenoid valve (standard) protects compressor in the event of leaks

- Pre-installed valves eliminate additional wiring to the thermostat

- Pressure tested by the manufacturer to ensure quality

- ETL certified

- No noise is produced in the wine cellar

- Occupies no space in the wine cellar

- Factory-wired for simple field installation

- Provides static pressure for duct runs up to 25 ft

- Insulated rust-proof aluminum housing

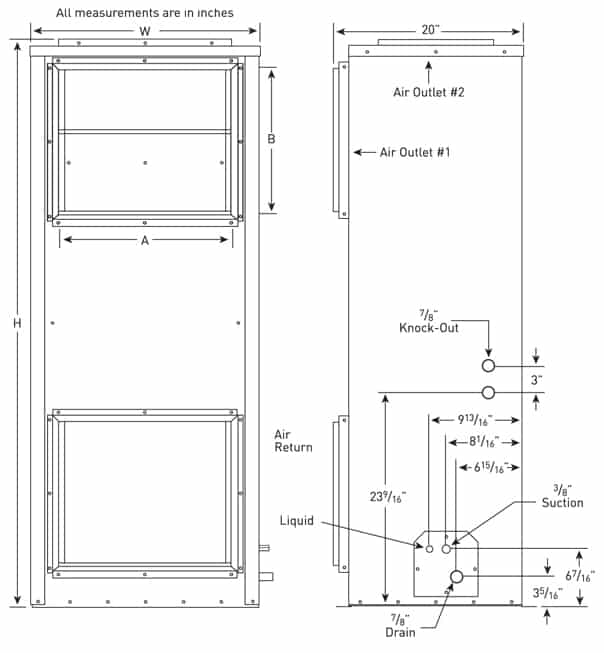

Mounting Diagrams

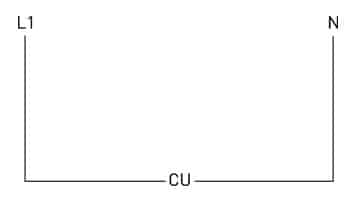

Condensing Unit Wiring

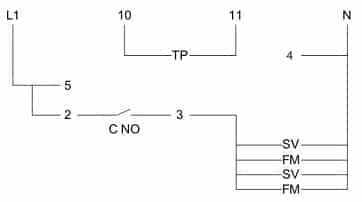

Fan Coil Wiring

Field Wiring

L1115V Line Voltage

NNeutral

SVSolenoid Valve

FMFan Motor

TPTemperature Probe

Back of Controller Connections

10Temperature Probe

11Temperature Probe

4Neutral

5115V Line Voltage

2Jumper from 5

3Switch Leg to Fan Coil

C NOInternal normally open contact

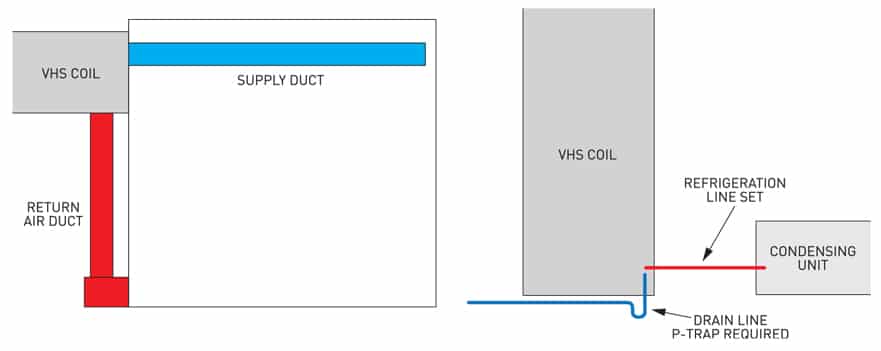

VHS Cooling Units System – Typical Installation

- The installation diagram shows the standard duct layout. The actual layout is to be determined by the installer.

- Ductwork not to exceed 50′ total length.

- For a short duct length mat, install a fan speed to slow down the fan speed.

- Keep line sets as short as possible.

- A pump controls the system’s down-control process. There is no control wiring between the thermostat and condensing unit.

- The drain line must always flow downhill to drain or pump.

- Standard line sets should be 50′ or less. Extended runs may require larger line sizes. 3 oz. oil should be added for every 10′ over 35′.

- The line connections at Fan Coil and Condensing Unit may not be the same as the required line sizes.

- An excessive number of turns will cause refrigerant flow problems. This action can cause early compressor failure. We recommend suction line accumulators. They are required accessories if the wine cellar is working lower than the standard 55-65° operating range from the wine cellar.

VHS Series – Vertical High Static / Air or Water Cooled w/ Digital Controller

System Information

The Vertical High Static (VHS) Systems are wine cellar cooling units intended to deliver refrigerated air to medium to high-temperature spaces. You will find these evaporators are powerful and can be situated as far up to twenty-five feet distant from the climate-controlled wine room. The cooled air is ducted back into the wine cellar, virtually eliminating any noise. These systems also prevent the inconvenience associated with evaporators placed in the wine cellar, which can free up storage space for wine bottles.

VHS evaporators are available in capacities from 1,800 to 20,000 BTUs every hour. To be used with an R134a refrigerant.

AVAILABLE OPTIONS

- Copper or coated coils for coastal/special applications

- Secondary drain pan for elevated and sensitive installations

- Stainless steel cabinets for high corrosive environments

- Eco-friendly water-cooled condensing units available

- Industrial applications available

Features

- Thermally protected permanently lubricated motor

- The automatic expansion valve (standard) ensures constant coil temperature to promote “Humidity Balance”

- Pump-down solenoid valve (standard) protects compressor in the event of leaks

- Pre-installed valves eliminate additional wiring to the thermostat

- Pressure tested by the manufacturer to ensure quality

- ETL certified

- No noise is produced in the wine cellar

- Occupies no space in the wine cellar

- Factory-wired for simple field installation

- Provides static pressure for duct runs up to 25 ft

- Insulated rust-proof aluminum housing

Condensing Unit Wiring

Fan Coil Wiring

Field Wiring

L1115V Line Voltage

NNeutral

SVSolenoid Valve

FMFan Motor

TPTemperature Probe

Back of Controller Connections

10Temperature Probe

11Temperature Probe

4Neutral

5115V Line Voltage

2Jumper from 5

3Switch Leg to Fan Coil

C NOInternal normally open contact

VHS Wine Cellar Coolin Units – Typical Installation

- The installation diagram shows the typical duct layout. The actual layout is to be determined by the installer.

- Ductwork not to exceed 50′ total length.

- For a short duct length mat, install a fan speed to slow down the fan speed.

- Keep line sets as short as possible.

- The system is controlled by a pump-down control system. There is no control wiring between the thermostat and condensing unit.

- The drain line must always flow downhill to drain or pump.

- Standard line sets should be 50′ or less. Extended runs may require larger line sizes and 3oz. oil must be added for every 10′ over 35′.

- The line connections at Fan Coil and Condensing Unit may not be the same as the required line sizes.

- An excessive number of turns will cause refrigerant flow problems. This could cause early compressor failure. Suction line accumulators are recommended. Required if working lower than the normal 55-65° operating range from the wine cellar.

VHS Series – Vertical High Static / Air or Water Cooled w/ Digital Controller

SYSTEM INFORMATION

The Vertical High Static (VHS) Systems are intended to deliver refrigerated air to medium to high-temperature spaces. You will find these evaporators powerful and can be situated as far up to twenty-five feet distant from the climate-controlled wine room. The cooled air is ducted back into the wine cellar, virtually eliminating any noise and of course, the inconvenience associated with evaporators that have to be placed in the wine cellar, this can also free up storage space otherwise lost.

VHS evaporators are available in capacities from 1,800 to 20,000 BTUs every hour. To be used with an R134a refrigerant.

Available Options

- Copper or coated coils for coastal/special applications

- Secondary drain pan for elevated and sensitive installations

- Stainless steel cabinets for high corrosive environments

- Eco-friendly water-cooled condensing units available

- Industrial applications available

Features

- Thermally protected permanently lubricated motor

- The automatic expansion valve (standard) ensures constant coil temperature to promote “Humidity Balance”

- Pump-down solenoid valve (standard) protects compressor in the event of leaks

- Pre-installed valves eliminate additional wiring to the thermostat

- Pressure tested by the manufacturer to ensure quality

- ETL certified

- No noise is produced in the wine cellar

- Occupies no space in the wine cellar

- Factory-wired for simple field installation

- Provides static pressure for duct runs up to 25 ft

- Insulated rust-proof aluminum housing

Condensing Unit Wiring

Fan Coil Wiring

Field Wiring

L1115V Line Voltage

NNeutral

SVSolenoid Valve

FMFan Motor

TPTemperature Probe

Back of Controller Connections

10Temperature Probe

11Temperature Probe

4Neutral

5115V Line Voltage

2Jumper from 5

3Switch Leg to Fan Coil

C NOInternal normally open contact

VHS Wine Cellar Cooling Units – Typical Installation

- The installation diagram shows the typical duct layout. The actual layout is to be determined by the installer.

- Ductwork not to exceed 50′ total length.

- For a short duct length mat, install a fan speed to slow down fan speed.

- Keep line sets as short as possible.

- The system is controlled by a pump-down control system. There is no control wiring between the thermostat and condensing unit.

- The drain line must always flow downhill to drain or pump.

- Standard line sets should be 50′ or less. Extended runs may require larger line sizes and 3oz. oil must be added for every 10′ over 35′.

- The line connections at Fan Coil and Condensing Unit may not be the same as the required line sizes.

- An excessive number of turns will cause refrigerant flow problems. This could cause early compressor failure. Suction line accumulators are recommended. Required if working lower than the normal 55-65° operating range from the wine cellar.

GO HERE TO SEE other wine cellar refrigeration units by US Cellar Systems.